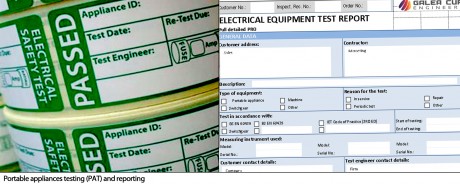

Portable Appliance Testing

PAT testing is the examination of electrical appliances and equipment to ensure they meet a minimum level of electrical safety and thereby help reduce the risk of injury or electrical fires that may occur in the workplace as well as commercial and domestic environments.

PAT testing is an essential practice that ensures that your employees are safe and your business fully functional. To meet these requirements, it is necessary to have in place a program of inspection and testing of portable appliances. PAT testing programmes are necessary for the prevention of damage from wear and tear, corrosion, excessive electrical loading and helps detect potential safety problems before they occur. Any electrical item which is connected to single-phase electrical power and supplied by a flexible cord and plug requires PAT testing.

Our experienced engineers conduct visual inspections, rigorous electrical and PAT testing and certification (including reports with detailed test results) to ensure your electrical equipment meets the exact requirements of BS7671 – Requirements for Electrical Installations. The electrical equipment undergoes a variety of tests, including:

- Visual Inspection: Formal visual inspection is performed and documented prior to the actual PAT testing since the most potential dangerous faults can be picked up by such inspections. Visual checks by our engineers may detect faults such as loss of earth integrity, deteriorating insulation integrity, contamination of internal and external surfaces and much more.

- Earth Bond Test: Tests the metal casing of equipment to confirm the integrity of the appliance earth conductor. A high A.C. current of 10amp or 25amp is injected between the earth bond terminal and the appliance’s earth pin.

- Insulation Test: This test checks the integrity of the insulation that is protecting users from the live parts of the appliance.

- Sub-Leakage Test: Any current leakage to earth will be detected by this test. This test can be carried out on all classes of equipment.

- Leakage Current Test: This test uses a leakage current tester which measures current leakage when the appliance under test is switched on.

- Polarity Test: This test is conducted to ensure that the live and neutral cable connections are to the appliance terminals are correct.

- Functional Test: This test is performed to ensure that the appliance is functioning correctly.

- Load Test: A test to determine whether the appliance fuses function properly. This test can be carried out on all classes of equipment.

- Barcoding and labelling of each appliance: A label is affixed on each appliance. The label includes the following information: Date of inspection, appliance barcode , next inspection/ test date, pass or fail.

Any electrical item which is connected to single-phase electrical power and supplied by a flexible cord and plug requires PAT testing.